Engineering Services

Building engineering design services involve the planning, analysis, and design of essential building systems to ensure safety, functionality, and efficiency. These services include structural, mechanical, electrical, and plumbing (SMEP) design. Engineers create detailed plans using advanced software to model and simulate building performance, optimizing factors like energy efficiency, durability, and cost-effectiveness. Key aspects include sustainable design, compliance with regulations, and integration with architectural vision. The goal is to deliver well-coordinated systems that meet client needs, from residential homes to commercial properties, ensuring reliable operation, ease of maintenance, and long-term value for the built environment.

Structural Design Lab

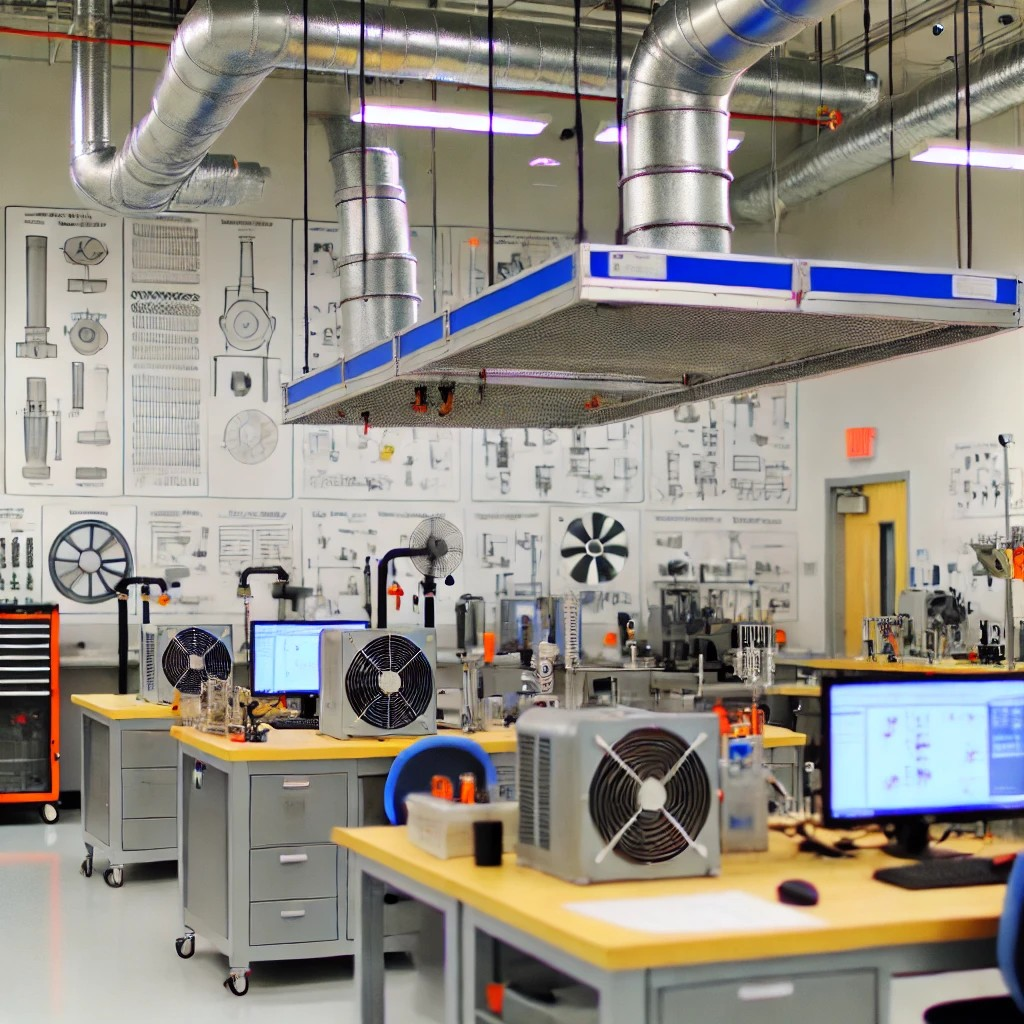

Mechanical engineering design services involve creating, analyzing, and optimizing mechanical systems and products.

These services include conceptual design, detailed engineering, and prototyping for machinery, equipment, HVAC systems, and structural components.

By leveraging CAD (Computer-Aided Design) tools, engineers create 3D models, run simulations, and perform stress analysis to ensure optimal performance, safety, and cost-efficiency.

Typical projects range from designing components for manufacturing to large-scale systems like energy plants. With a focus on precision and innovation, these services help transform ideas into functional products while meeting regulatory standards and client requirements across various industries, including construction, automotive, and aerospace.

Mechatronics Design Lab

This includes designing power distribution, lighting, fire alarms, and communication systems to ensure safety, efficiency, and compliance with local codes and standards.

Engineers develop detailed schematics, load calculations, panel schedules, and system layouts. They also incorporate energy-saving technologies and automation. The design process includes coordination with architects, mechanical engineers, and construction teams.

From initial concept through to construction documentation, electrical engineering design ensures that power systems are reliable, meet client needs, and integrate seamlessly with other building elements.

Mechanical Design Lab

Public Health Engineering (PHE) design services focus on creating efficient systems for water supply, drainage, sanitation, and waste management in buildings. This includes designing potable water distribution, sewage systems, rainwater harvesting, and sustainable waste disposal strategies.

PHE services also cover fire protection, stormwater management, and graywater recycling to ensure buildings meet hygiene and environmental standards.

The designs prioritize health, safety, and regulatory compliance, integrating smart technologies and automation for efficiency.

Public Health Engineers work closely with architects and other engineers to deliver systems that enhance well-being while minimizing environmental impact and conserving resources.

Electrical Design Lab

Structural engineers assess factors like material strength, load distribution, and environmental impact to create efficient designs. They work on everything from foundations to frameworks, integrating safety with functionality.

Using advanced software and simulations, they predict structural performance under various conditions, optimizing designs for cost-effectiveness and longevity.

Structural engineering design services are essential for creating safe and resilient built environments, whether for residential, commercial, or industrial projects.

Building Engineering Design Services

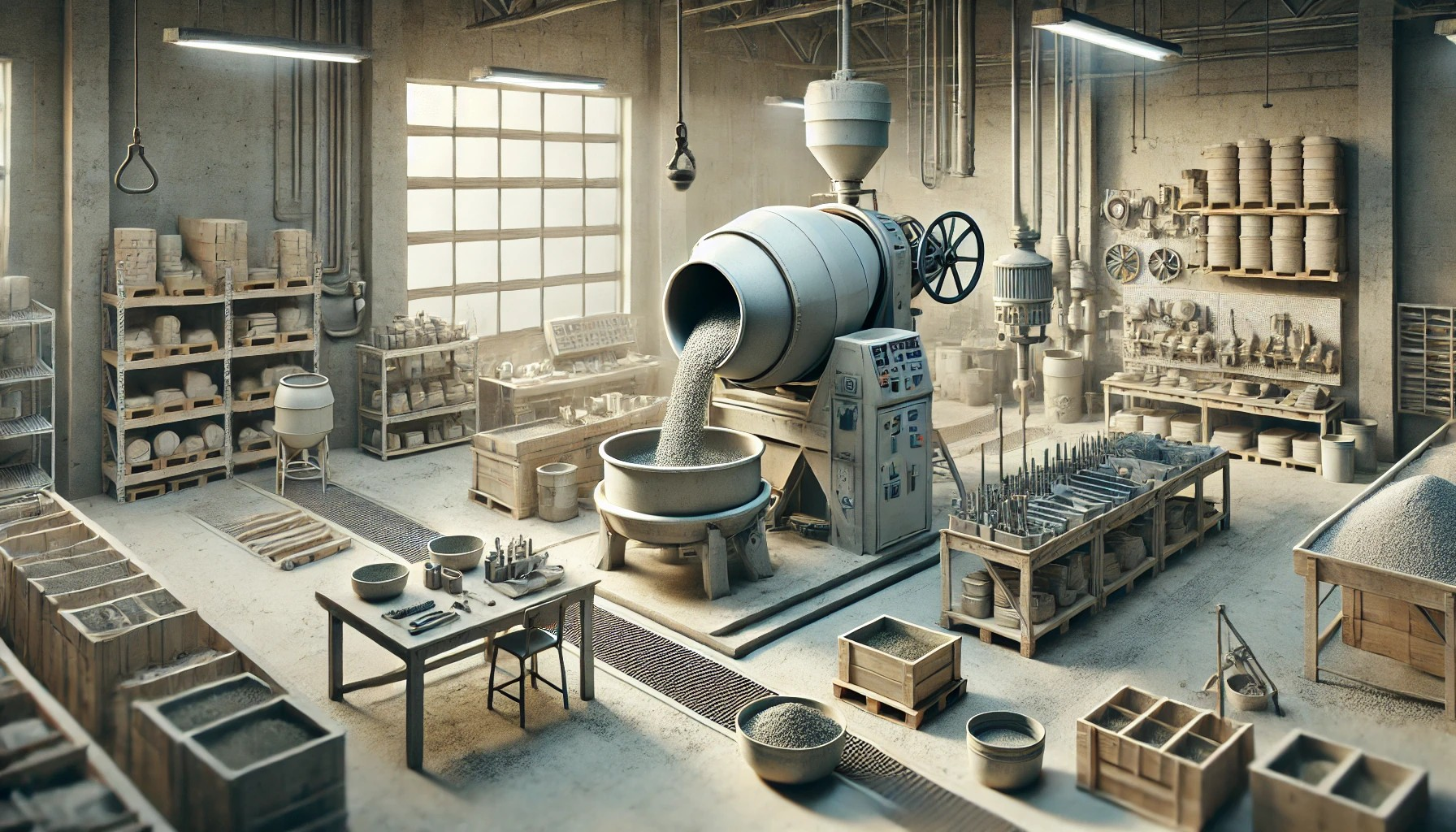

Case Study: Development of a Sustainable Concrete Block Using the Structural Design Lab

Project Overview

This case study highlights the innovative work conducted in our Structural Design Lab to create a new type of concrete block that integrates sustainable materials into the cement mix, aimed at reducing embodied carbon and utilizing recycled materials. The goal was to develop a concrete block that maintains structural integrity while significantly lowering its environmental impact.

Objectives

The primary objectives of this project were:

1. Reduce Embodied Carbon: To minimize the carbon footprint of the concrete by incorporating low-carbon materials in the cement mix.

2. Utilize Recycled Materials: To include recycled aggregates and industrial by-products in the concrete mix, reducing the reliance on virgin materials.

3. Maintain Structural Integrity: To ensure that the new concrete block meets or exceeds existing standards for strength, durability, and longevity.

4. Promote Sustainability: To create a commercially viable product that aligns with sustainable construction practices.

Design and Development Process

1. Material Selection:

- The first step involved selecting sustainable materials that could replace traditional cement components. Fly ash, a by-product of coal combustion, and slag, a by-product of steel manufacturing, were identified as potential substitutes. These materials have lower embodied carbon compared to Portland cement.

- Recycled aggregates, including crushed concrete and glass, were chosen to replace natural aggregates like sand and gravel. These materials were selected based on their availability, cost-effectiveness, and compatibility with the cement mix.

2. Mix Design and Testing:

- Using our Structural Design Lab’s advanced mixing and testing equipment, various concrete mixes were formulated. The lab’s computer-controlled batching systems allowed for precise adjustments to the mix ratios, enabling the team to experiment with different proportions of sustainable materials.

- The lab’s material testing equipment, including compression testers and curing chambers, was used to evaluate the strength, workability, and curing characteristics of each mix. The goal was to achieve a balance between sustainability and performance.

3. Prototyping and Structural Analysis:

- Once a promising mix was identified, the lab’s 3D concrete printing technology was used to create prototypes of the new concrete blocks. This allowed for rapid prototyping and testing of various block shapes and sizes.

- Structural analysis was performed using the lab’s finite element modeling (FEM) software to simulate the performance of the blocks under various load conditions. This ensured that the blocks would meet the necessary structural requirements for use in construction.

4. Environmental Impact Assessment:

- The lab’s environmental impact assessment tools were used to calculate the embodied carbon of the new concrete blocks. The results showed a significant reduction in carbon emissions compared to traditional concrete blocks, primarily due to the use of fly ash, slag, and recycled aggregates.

- Life cycle assessments (LCA) were conducted to evaluate the long-term environmental benefits of the new blocks, including energy savings and waste reduction.

Results and Outcomes

- Embodied Carbon Reduction: The new concrete blocks achieved a 40% reduction in embodied carbon compared to traditional concrete blocks. This was primarily due to the substitution of Portland cement with fly ash and slag, as well as the use of recycled aggregates.

- Material Efficiency: The incorporation of recycled materials not only reduced the environmental impact but also lowered the production cost of the concrete blocks, making them a cost-effective alternative for sustainable construction projects.

- Structural Performance: The structural analysis and testing confirmed that the new blocks met or exceeded industry standards for compressive strength, durability, and resistance to weathering. This ensured that they could be used in a wide range of construction applications.

- Commercial Viability: The project demonstrated that sustainable concrete blocks could be produced at scale without compromising performance or significantly increasing costs. This opened up new opportunities for eco-friendly construction materials in the market.

Challenges and Solutions

- Material Compatibility: One of the challenges was ensuring the compatibility of recycled materials with the cement mix. This was addressed through extensive testing and adjustments to the mix design, ensuring that the final product maintained the necessary properties for structural use.

- Scaling Production: Scaling the production of sustainable concrete blocks required optimizing the mix design for large-scale manufacturing. This involved working closely with material suppliers and adjusting the mix to accommodate variations in the quality of recycled materials.

- Market Acceptance: Introducing a new product to the market required educating stakeholders about the benefits of sustainable concrete. This was achieved through demonstrations, case studies, and partnerships with construction companies interested in sustainable building practices.

Conclusion

The development of this sustainable concrete block in our Structural Design Lab represents a significant advancement in eco-friendly construction materials. By integrating low-carbon and recycled materials into the cement mix, we were able to create a product that not only reduces the environmental impact of construction but also meets the rigorous demands of modern building projects. This project showcases the potential for innovation in structural design and underscores the importance of sustainability in the construction industry.

The success of this project sets a precedent for future developments in sustainable building materials, and the lessons learned will inform ongoing research and development efforts in the field of structural engineering.